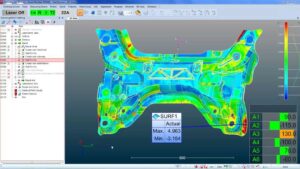

ATT Metrology utilizes many sophisticated software programs to perform comprehensive measurement data analysis for our customers.

The software allows comparisons of points collected by any three-dimensional measurement system to your CAD surface model and provides a variety of text and graphical reporting capabilities. The data used for comparison can be ATT measurements or customer provided data that is analyzed “off-line.” Customized and simplified metrology reports are a specialty at ATT.

Reduce downtime and scrap rates with data analysis.

Together, dimensional management, GD&T analysis, and Monte Carlo methods form a comprehensive approach to ensuring that a product meets the desired specifications and functions as intended. Dimensional management provides the framework for controlling and optimizing the dimensions and tolerances of the product, GD&T analysis provides the tools for specifying and communicating the allowable variations, and Monte Carlo methods provide the means for analyzing and optimizing the manufacturing process to achieve the desired product quality.

Types of Metrological Analysis Available:

- Best Fit Analysis of Point Data to Surface Models

- Tool & Part Comparisons to Engineering CAD Models/Datasets

- Surface Creation from Measurement Data

- Dimensional Management (DM)

- GD&T Stackup Analysis, including Monte Carlo Methods

- Statistical Process Control (SPC) or Statistical Quality Control (SQC)