University of Arizona – Supporting Research and Education

In 2003, ATT had the pleasure of assisting The University of Arizona investigate the viability of a laser tracker system to be used as a tool in their Optical Shop. Dr. Jim Burge said the following: “We would like to thank you for the donation of your time and access to the equipment that allowed…

Read MoreBombardier Aerospace – Verification of AJFA Wing Tools

ATT utilized the Leica AT401 Tracker, the Faro Xi Tracker and the Wild Optic Level, to complete all of the measurements on the Wing Tools. ATT’s initial contract called for validation of previously constructed AJFA Wing Tools Units 1 and 2. After arriving on site, the customer requested that level buttons be added to the…

Read MoreRemmele Engineering C-130 Cargo Door Scan

ATT Metrology was selected by Remmele to measure all of the tooling for the C-130 forward Passenger door and to scan an existing door on the C-130. The data would be used to Reverse Engineering. The purpose of the project was to evaluate the process of these doors modernize production on future models of this…

Read MoreBonneville Dam

ATT Metrology Solutions (ATT) was contracted by Alstom to support the precision alignment of the #11 stator of the Hydro-Electric Generator at the Bonneville Dam at Cascade Locks, Oregon. ATT aligned the Stator level to the center shaft of the generator using a laser tracker. ATT measured multiple points on the upper and lower sections…

Read MoreParabolic Trough Intercept Factor

ATT Metrology Solutions (ATT) was selected by Gossamer Space Frames Inc. (Gossamer) to provide precision measurement services to calculate the intercept factor of parabolic mirrors in relation to light refraction to a focal point. ATT developed a targeting strategy for the photogrammetry system that would optimize the data collection and give the most accurate results.…

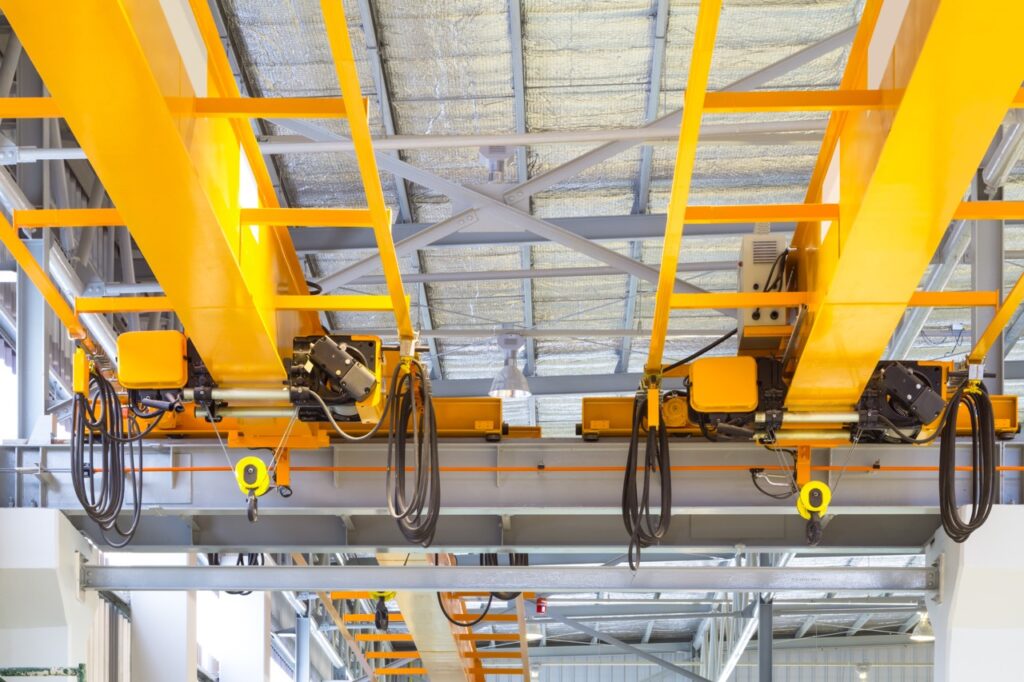

Read MoreBoeing 787 Final Assembly – Crane Rail System

ATT Metrology Solutions (ATT) was chosen by ACECO to provide precision alignment services for the new overhead crane system in the 787 Boeing Final Assembly Plant in Charleston, SC. The plan required measurements to be taken over 1000 feet in distance and 80 feet above the production floor. ATT utilized state-of-the-art Laser Trackers and the…

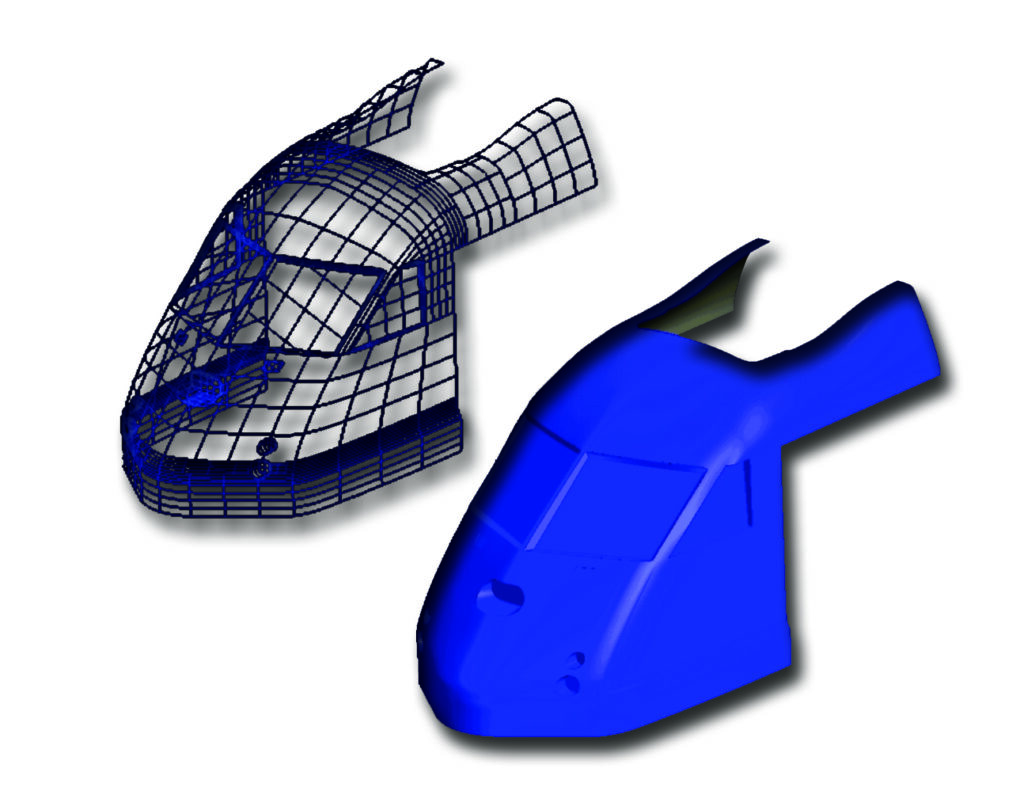

Read MoreBullet Train Reverse Engineering Project

ATT Metrology Solutions was contracted to perform the reverse engineering of an existing model master into a CAD model for Super Steel. The project required the digitizing of the 10-ft. by 8-ft. by 15-ft. model using a laser tracker. ATT Technicians collected nearly 60,000 points on the model master over a two-day period. The data…

Read MoreLaser Tracker Training & Process Documentation Development

ATT Metrology Solutions was contracted by Raytheon to assist them in improving the implementation of their laser tracker systems by performing advanced training for their Tool Fabrication and Quality personnel. ATT also assisted in developing documentation to ensure the operators were following the best practices known in the industry to achieve optimal results. ATT succeeded…

Read MoreJoint Strike Fighter Fixture Alignment

ATT Metrology Solutions was contracted by Pratt & Whitney to inspect a JSF Engine Test Fixture using a laser tracker. The inspection was to provide a calibration certificate for the tool for allowing test fitting of engine components from various manufacturers around the world. ATT found some areas of the tool where details were outside…

Read MoreMobile Launch Vehicle Alignment and Verification

ATT Metrology Solutions was contracted to perform inspections of the attach points for the mobile launch vehicles and determine the adjustments necessary to ensure that the launch canisters would properly attach to the vehicles without requiring special adjustment or rework. ATT was able to complete the measurements of the first three vehicles identified with such…

Read More