Digital twin solutions revolutionized various industries, providing unparalleled insights and predictive capabilities. As the digital landscape evolves, the demand for accurate and comprehensive digital twin data collection services has surged.

From manufacturing and aerospace to healthcare and urban planning, digital twins provide organizations with valuable insights and predictive capabilities that drive efficiency, reduce costs, and enhance their decision-making processes.

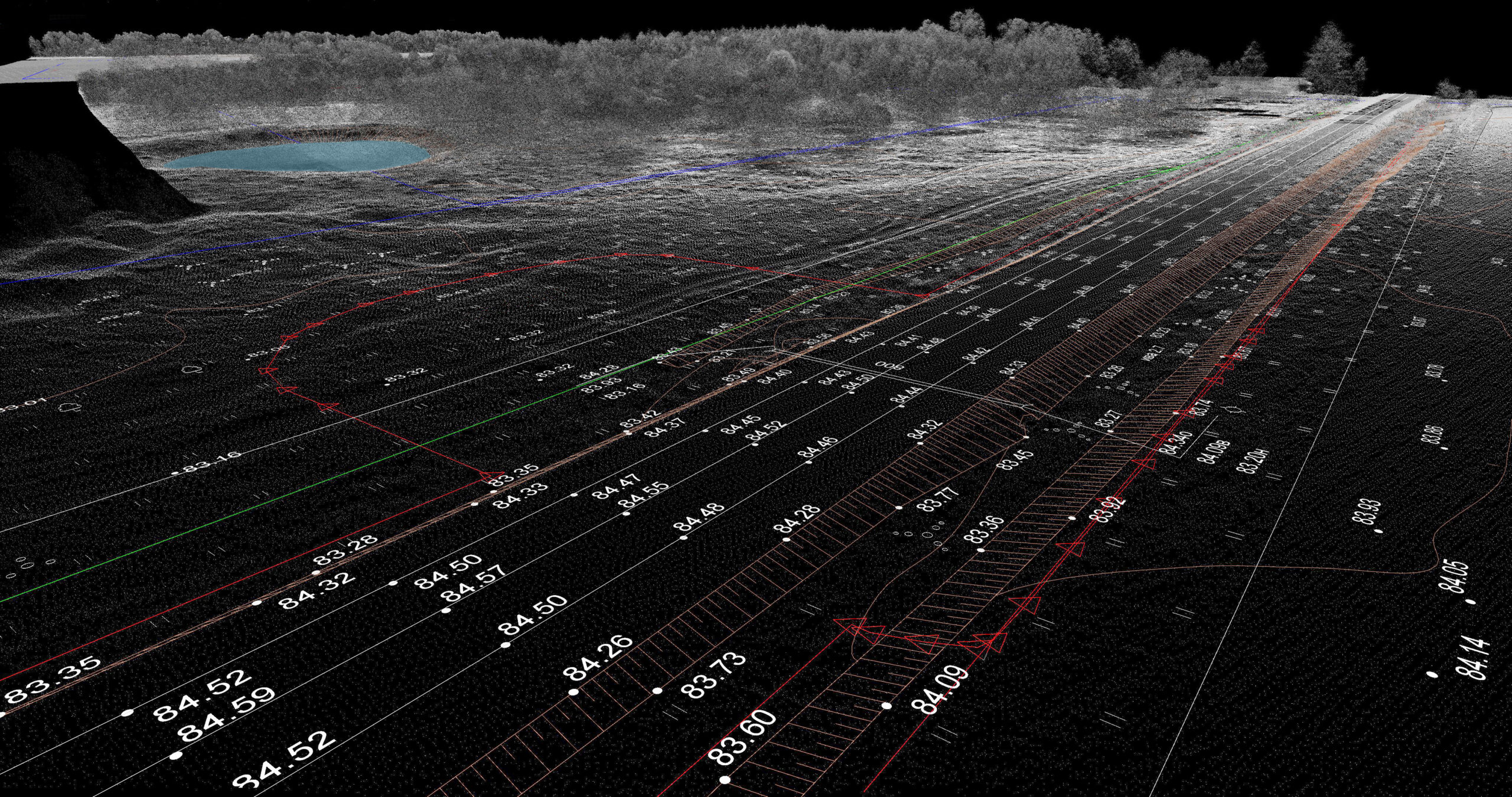

ATT Metrology stands at the forefront of this transformation, offering state-of-the-art digital twin 3D modeling service that caters to diverse industry needs. Whether it’s through meticulous 3D laser scanning or comprehensive as-built documentation, ATT Metrology’s services empower industries to harness the full potential of digital twin technology, driving innovation and excellence in their respective fields.

What is a Digital Twin?

Digital twin services create virtual replicas of physical assets, processes, or systems that mirror real-world entities in every detail. These digital counterparts provide a comprehensive understanding and analysis of their physical counterparts, enabling organizations to optimize performance, predict outcomes, and drive efficiencies.

Recent advancements in sensor technologies, data analytics, and computing power have significantly enhanced the capabilities of digital twins. For instance, integrating AI and machine learning algorithms brings a new dimension to digital twins, transforming them from static representations to dynamic decision-making platforms.

AI-equipped digital twins can optimize energy consumption, predict traffic patterns, and facilitate self-learning machines and first-time-right production, among other applications. This evolution underscores a paradigm shift, enabling digital twins to drive insights and optimizations in complex systems, ultimately fostering innovation in fields like urban management and sustainable production.

Metrology Best Practices for Accurate Digital Twin Data Collection

Accurate digital twin data collection is fundamental to the integrity and effectiveness of digital twin solutions. Implementing rigorous metrology best practices ensures the precision and reliability of the digital twins, enabling them to serve as accurate reflections of their physical counterparts.

Building an accurate digital twin requires meticulous data collection, rigorous processes, and the expertise of skilled professionals. Here are some metrology best practices that ensure the fidelity and utility of digital twin solutions:

Utilize the Right Instruments and Tools

The right tools and instruments are essential for creating a precise digital twin. Advanced technologies like LiDAR (Light Detection and Ranging) offer the high accuracy required for making reliable digital twins, capturing the intricacies of physical spaces down to minute details.

In expansive or difficult-to-access areas, drones equipped with laser scanning technology provide an efficient solution, ensuring comprehensive data acquisition from various angles.

Equally important is the use of robust software solutions such as CAD (Computer-Aided Design) and BIM (Building Information Modeling) platforms, which are crucial for processing and analyzing the collected data into usable formats.

Implement Structured Data Collection Processes

A structured approach to data collection is critical for accuracy. This begins with comprehensive site surveys involving detailed evaluations to capture every aspect of the physical environment, including structural dimensions, spatial relationships, and existing conditions.

Regular, consistent data validation against known standards ensures the collected data remains accurate and reliable. This process often involves cross-referencing measurements and performing quality checks.

Leverage Expertise and Collaboration

The successful creation of digital twins depends on the involvement of skilled professionals who deeply understand metrology and the specific requirements of digital twin projects. Engaging experienced metrology experts ensures that data collection is both accurate and efficient.

Maintain High Standards of Accuracy and Precision

Maintaining high standards of accuracy and precision is a fundamental aspect of digital twin services. This starts with equipment calibration, which ensures accurate measurements. Additionally, detailed documentation of all data collection processes, including instrument settings, environmental conditions, and measurement techniques, is crucial for maintaining transparency and traceability throughout the project.

Integrate Advanced Technologies

Incorporating advanced technologies can significantly enhance the accuracy and functionality of digital twins. AI and machine learning can play a pivotal role in data analysis, helping to identify patterns and predict outcomes. These technologies improve the accuracy of digital twins by continuously learning from new data.

Furthermore, IoT sensors allow for gathering real-time data, providing up-to-date information that reflects the current state of the physical environment. This integration ensures that digital twins remain dynamic and responsive to changes.

Adhere to Industry Standards and Protocols

Adherence to industry standards and protocols is essential for ensuring consistency and reliability. Following guidelines set by organizations such as ISO (International Organization for Standardization) helps maintain uniformity in data collection and processing.

Regular audits of data collection processes and tools are also vital as they ensure ongoing compliance with industry standards. Doing so can help identify areas for improvement and ensure that the data remains accurate and reliable.

The Tech Industry’s Race for Digital Twin Data: Feeding AI and AR/VR Innovations

The tech industry is experiencing an arms race for digital twin data to fuel advancements in AI and AR/VR technologies. This data is indispensable for creating realistic and interactive digital environments, which are foundational to innovations in spatial computing, virtual reality, and augmented reality.

Companies like Apple are leading the charge with devices such as the Apple Vision Pro, which herald a new era of spatial computing. These advancements rely heavily on accurate and up-to-date digital twin data to deliver immersive experiences and enhance user interaction. Regular data collection is essential to capture the dynamic nature of physical environments and ensure that digital twins remain relevant and accurate.

Harnessing Digital Twin Data for Enhanced Simulation Software in Critical Applications

Digital twin data has immense potential in enhancing simulation software used in critical applications such as rescue response, traffic planning, and military strategy. Leveraging platforms like Unity and Unreal Engine can transform digital twins into interactive simulations that provide valuable insights and training opportunities.

Rescue Response

Digital twins enable the creation of realistic training environments for rescue operations. For instance, the Fire Department of New York (FDNY) uses digital twin technology to simulate high-rise building fires, which helps responders develop effective strategies and improve their response times, ultimately saving lives.

These simulations allow for testing various disaster scenarios, preparing responders for a wide range of emergencies and enhancing their on-ground performance.

Traffic Planning

Urban planners can use digital twins to simulate traffic flow and identify bottlenecks. A notable example is the city of Singapore, which uses digital twin technology to manage its traffic systems.

By simulating different traffic scenarios, planners can design more efficient transportation networks, reduce congestion, and improve overall mobility. This data-driven approach helps create sustainable urban environments and enhances the daily commute for citizens.

Military Strategy

Digital twins are increasingly being used in training and strategy development. The U.S. Army, for instance, employs digital twin technology to simulate battlefield scenarios. These simulations allow military personnel to refine tactics, enhance decision-making, and conduct virtual mission rehearsals. By providing a risk-free environment for training, digital twins help prepare soldiers for real-world operations.

Digital Transformation and Industry 4.0: Leveraging Digital Twin Data

The wave of digital transformation and Industry 4.0 initiatives is revolutionizing the manufacturing and industrial sectors, with digital twin technology at the forefront. Factories are increasingly leveraging digital twin data to enhance various aspects of their operations, including the following:

- Installation and Decommissioning Planning: Digital twins provide a detailed and comprehensive view of factory layouts and equipment, making the planning process for installations and decommissioning much more precise, minimizing disruptions and maintaining operational continuity.

- Workflow Optimization: By analyzing the data from digital twins, manufacturers can pinpoint inefficiencies in their workflows and implement targeted improvements. For General Electric (GE), digital twins help optimize the performance of its jet engines and turbines, leading to significant gains in efficiency and cost savings.

- Production Quality and Safety Monitoring: Digital twins enable real-time monitoring of production processes, allowing manufacturers to promptly detect and address quality and safety issues. This proactive approach not only enhances product quality but also ensures a safer working environment for employees.

Harness the Power of Digital Twin Modeling With ATT Metrology

Navigating today’s dynamic technological landscape underscores the critical importance of defining “What is a digital twin?” and knowing how to build a digital twin with precise and comprehensive data collection. As industries accelerate their adoption of AI, AR/VR, and critical simulation applications, the demand for high-fidelity digital twins will continue to explode.

At ATT Metrology, we stand at the forefront of this digital revolution with our advanced digital twin scanning and 3D modeling service. By integrating cutting-edge metrology practices with extensive industry expertise, as digital twin solution providers we deliver digital twin modeling that is not just accurate but transformative. Our solutions empower businesses to gain actionable insights, optimize operations, and drive innovation.

Partner with ATT Metrology to harness the full potential of digital twin technology. Let us help you confidently navigate the complexities of digital transformation and Industry 4.0.

Contact us today and discover how our tailored digital twin solutions can propel your business forward.